- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

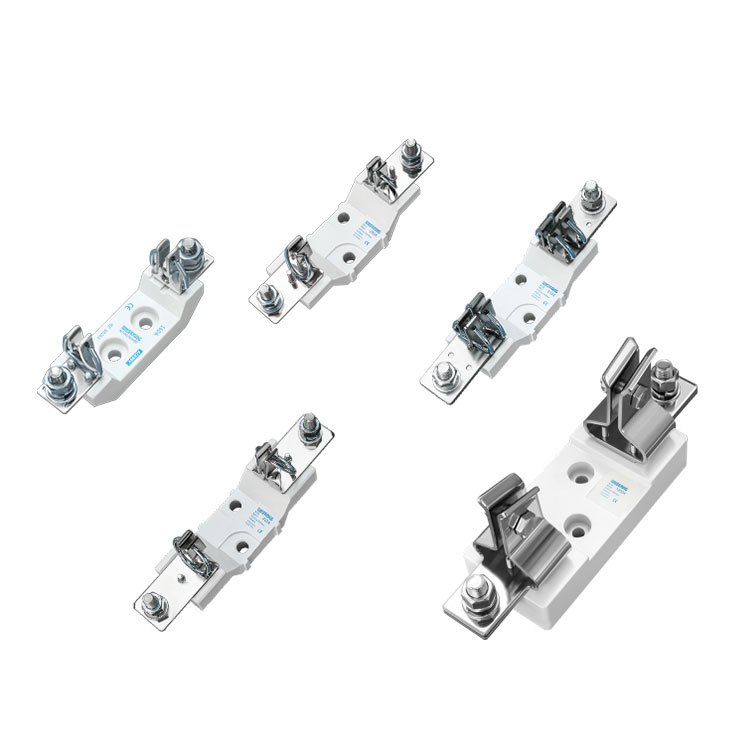

NT00 NT1 NT2 NT3 NT4 Fuse Links

WESTKING NH(NT) FUSE is suitable for 50HZ or 60HZ, has obtained CCC certification, and is commonly used in industrial and communication fields. Unlike other factory-made products, WESTKING's NH(NT) FUSE can meet the application requirements in three different voltage levels, 500VAC, 690VAC, and 440VDC. It uses high-strength ceramic and purple copper as the connection, which has the advantages of low temperature rise and low power consumption.

Send Inquiry

WESTKING NH(NT) FUSE is designed as a plug-in type fuse, including:

Fuse base (including terminal cover and phase shield)

Fuse connection in contact with the blade

Fuse replacement device (low-voltage HRC fuse puller)

The "gG" type NH fuse is a full-range breaking capacity fuse, used to protect cables and equipment. They can interrupt any current surge, from the lowest fusing current to breaking capacity. Therefore, they can be used alone as protection and also protect electrical equipment and industrial installations from the impact of very high short-circuit currents.

Technical data

| Type | Rated voltage | Rated currents |

| NH00(NT00)-Amp | 500VAC/690VAC/250VDC | 4A-6A-10A-16A-20A-25A-32A-36A40A-50A-63A-80A-100A-125A-160A |

| NH1(NT1)-Amp | 500VAC/690VAC/440VDC | 63A-80A-100A-125A-160A-200A-224A-250A |

| NH2(NT2)-Amp | 500VAC/690VAC/440VDC | 125A-160A-200A-250A-300A-315A-355A-400A |

| NH3(NT3)-Amp | 500VAC/690VAC/440VDC | 315A-355A-400A-425A-500A-630A |

| NH4(NT4)--Amp | 400VAC/690VAC/440VDC | 800A-1000A-1250A |

Standards

IEC60269.1

IEC60269.2

DIN43620

RoHS compliant

REACH declaration available upon request

KEY FEATURES/ADVANTAGES

High breaking capacity

Various ratings for current and voltage levels

Simple structure, easy to install and maintain

Good environmental adaptability and durability

APPLICATIONS

Industrial Power Distribution Systems:

Building Electrical Systems

Power Systems

Renewable Energy Systems

Transportation

Electronic Equipment and Control Systems

Certifications

• is09001 iatf16949 CCC

Origin

China

NH00(NT00) knife fuse link

| Type | Rated current(A) | Rated voltage | Breaking capacity | Power(w) | Weight(g) |

| NH00 NT00 Fuse link | 4 | 500VAC/690VAC/250VDC | 120kA/50kA/100kA | 1.5 | 200 |

| 6 | 500VAC/690VAC/250VDC | 120kA/50kA/100kA | 1.6 | ||

| 10 | 500VAC/690VAC/250VDC | 120kA/50kA/100kA | 1.7 | ||

| 16 | 500VAC/690VAC/250VDC | 120kA/50kA/100kA | 2.0 | ||

| 20 | 500VAC/690VAC/250VDC | 120kA/50kA/100kA | 2.5 | ||

| 25 | 500VAC/690VAC/250VDC | 120kA/50kA/100kA | 3.1 | ||

| 32 | 500VAC/690VAC/250VDC | 120kA/50kA/100kA | 3.5 | ||

| 36 | 500VAC/690VAC/250VDC | 120kA/50kA/100kA | 3.8 | ||

| 40 | 500VAC/690VAC/250VDC | 120kA/50kA/100kA | 4.0 | ||

| 50 | 500VAC/690VAC/250VDC | 120kA/50kA/100kA | 5.3 | ||

| 63 | 500VAC/690VAC/250VDC | 120kA/50kA/100kA | 6.1 | ||

| 80 | 500VAC/690VAC/250VDC | 120kA/50kA/100kA | 6.9 | ||

| 100 | 500VAC/690VAC/250VDC | 120kA/50kA/100kA | 10.0 | ||

| 125 | 500VAC/690VAC/250VDC | 120kA/50kA/100kA | 11.0 | ||

| 160 | 500VAC/690VAC/250VDC | 120kA/50kA/100kA | 12.0 |

NH1(NT1) knife fuse link

| Type | Rated current(A) | Rated voltage | Breaking capacity | Power(w) | Weight(g) |

| NH1 NT1 Fuse link | 63 | 500VAC/690VAC/440VDC | 120kA/50kA/100kA | 7.5 | 400 |

| 80 | 500VAC/690VAC/440VDC | 120kA/50kA/100kA | 8.3 | ||

| 100 | 500VAC/690VAC/440VDC | 120kA/50kA/100kA | 12.0 | ||

| 125 | 500VAC/690VAC/440VDC | 120kA/50kA/100kA | 13.4 | ||

| 160 | 500VAC/690VAC/440VDC | 120kA/50kA/100kA | 16.5 | ||

| 200 | 500VAC/690VAC/440VDC | 120kA/50kA/100kA | 20.0 | ||

| 224 | 500VAC/690VAC/440VDC | 120kA/50kA/100kA | 22.3 | ||

| 250 | 500VAC/690VAC/440VDC | 120kA/50kA/100kA | 23.0 |

NH2(NT2) knife fuse link

| Type | Rated current(A) | Rated voltage | Breaking capacity | Power(w) | Weight(g) |

| NH2 NT2 Fuse link | 125 | 500VAC/690VAC/440VDC | 120kA/50kA/100kA | 21.0 | 610 |

| 160 | 500VAC/690VAC/440VDC | 120kA/50kA/100kA | 22.5 | ||

| 200 | 500VAC/690VAC/440VDC | 120kA/50kA/100kA | 27.0 | ||

| 250 | 500VAC/690VAC/440VDC | 120kA/50kA/100kA | 28.6 | ||

| 300 | 500VAC/690VAC/440VDC | 120kA/50kA/100kA | 32.0 | ||

| 315 | 500VAC/690VAC/440VDC | 120kA/50kA/100kA | 32.4 | ||

| 355 | 500VAC/690VAC/440VDC | 120kA/50kA/100kA | 33.5 | ||

| 400 | 500VAC/690VAC/440VDC | 120kA/50kA/100kA | 34.0 |

NH3(NT3) knife fuse link

| Type | Rated current(A) | Rated voltage | Breaking capacity | Power(w) | Weight(g) |

| NH3 NT3 Fuse link | 315 | 500VAC/690VAC/440VDC | 120kA/50kA/100kA | 35.0 | 820 |

| 355 | 500VAC/690VAC/440VDC | 120kA/50kA/100kA | 36.0 | ||

| 400 | 500VAC/690VAC/440VDC | 120kA/50kA/100kA | 38.1 | ||

| 425 | 500VAC/690VAC/440VDC | 120kA/50kA/100kA | 40.1 | ||

| 500 | 500VAC/690VAC/440VDC | 120kA/50kA/100kA | 45.2 | ||

| 630 | 500VAC/690VAC/440VDC | 120kA/50kA/100kA | 48.0 |

NH4(NT4) knife fuse link

| Type | Rated current(A) | Rated voltage | Breaking capacity | Power(w) | Weight(g) |

| NH4 NT4 Fuse link | 800 | AC400V/AC690V/DC440V | 100kA/50kA/100kA | 75.0 | 1950 |

| 1000 | AC400V/AC690V/DC440V | 100kA/50kA/100kA | 90.0 | ||

| 1250 | AC400V/AC690V/DC440V | 100kA/50kA/100kA | 110.0 |

Time-current rang of"gG"fuse links

NH FUSE LINK

cross-section schematic diagram

The typical structure of the NH (NT) fuse involves placing a fuse element between two specific blade contacts and encapsulating it within a ceramic tubular insulator with an elliptical or rectangular cross-section. The blade contacts are fixed to an end plate with a gripping lug that is compatible with a standard NH replacement handle, allowing the fuse to be inserted and removed. An indicator device, either a spring-loaded indicator on the outer end surface or a button indicator in front of the fuse, will be pushed open when the indicator wire melts to indicate that the fuse has operated.

The fuse element, which determines the time-current characteristics of the fuse and its temperature rise, is made of copper or silver tape and is carefully and precisely manufactured. The uniform tape thickness, good conductivity, and high-precision cutting ensure low power dissipation and compliance with the specified time-current characteristics.

The ceramic body prevents hot gases and liquefied metal from being ejected into the environment. It is made of high-quality industrial ceramic material such as talc or alumina, which can withstand high temperatures and pressures generated during operation.

The end plate has a gripping lug that is compatible with a standard NH replacement handle, allowing the fuse to be inserted and removed with the handle. Together with the ceramic tube, the end plate forms a pressure-resistant shell for arc switching.

Silica sand is essential for current limiting. WESTKING New Energy Company generally uses crystalline silica sand with high chemical and mineralogical purity (silicon oxide content greater than 99.9%) that is completely free of moisture after drying. The specified particle size distribution and optimal filling density of the silica sand are basic requirements for switching function.

The indicator device can quickly detect the operating fuse. If it has a high enough spring force, it can also serve as a striker to operate a miniature switch or a release device.

Solder can convert the time-current characteristics to a lower melting current. When selecting solder, special attention should be paid to the alloying effect of the solder on the soldering point when it melts. The solder must be soldered in the correct position and the amount of solder must be appropriate.

The blade contacts are used to electrically and mechanically connect the fuse body and base, and are made of copper or copper alloy, with a silver-plated surface. When used in special applications in corrosive gases, plated contacts with tin or nickel are also used.

With its high-quality materials and exquisite craftsmanship, the WESTKING NH fuse provides a reliable safety guarantee for power transmission and distribution. During use, attention should be paid to detection and maintenance to ensure the good condition of each component, ensuring the safe operation of electrical equipment.