- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

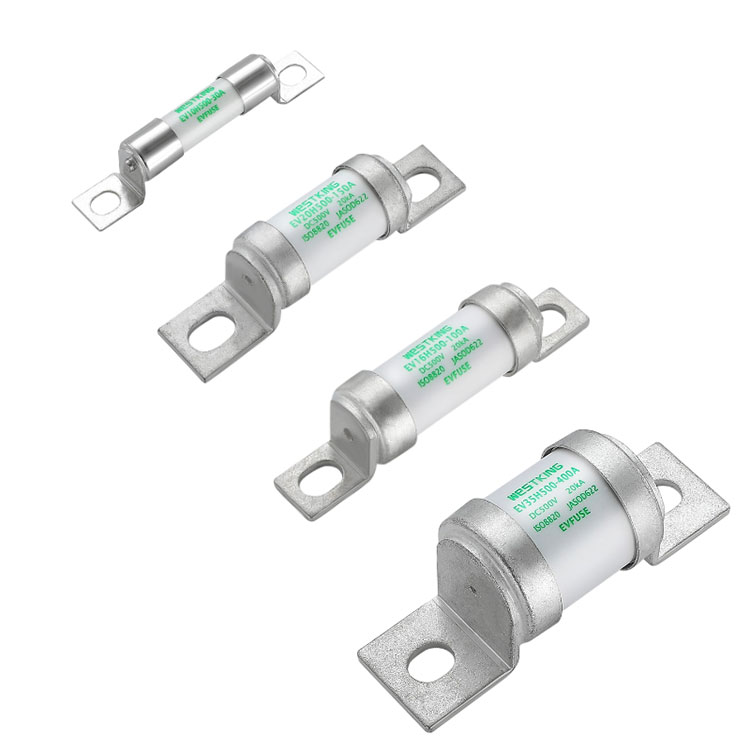

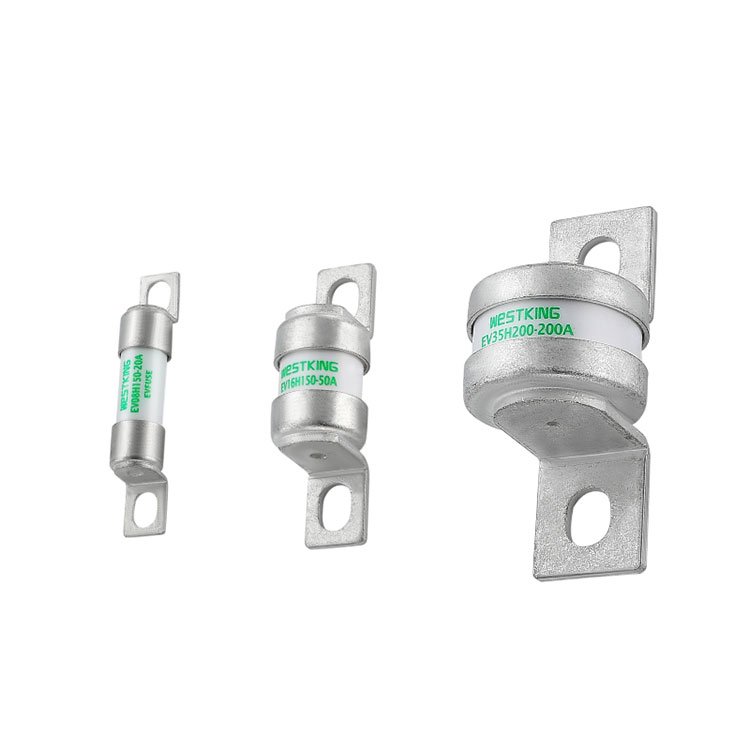

H EV Fuse 500VDC Series

Westking EVFUSE® series are designed for electric vehicles (EV) with Type H, 500VDC voltage. They are suitable for protecting battery packs of electric vehicles with a voltage of less than or equal to 500VDC, commonly used in passenger vehicles. The structure and characteristics of these fuses fully comply with the application conditions of new energy electric vehicles, featuring a bolted tightening structure and high-alumina high-temperature ceramic materials. These fuses offer market-leading compactness, impact resistance, and lifetime durability simulation functions, providing high-performance DC protection for drive, auxiliary, and battery systems.

Send Inquiry

WESTKING 500VDC BATTERY PACK FUSES provide dependable and secure protection for electric vehicles, resistant to vibration and capable of withstanding high and low temperatures. As one of the top choices for new energy electric vehicles in the Chinese market, these fuses showcase their outstanding performance and reliability in various scenarios, ensuring safety and stability for sustainable transportation.

Technical data

| Type | Rated voltage | Rated currents |

| EV10H500-(Amp) | 500VDC | 10A-50A |

| EV16H500-(Amp) | 500VDC | 20A-100A |

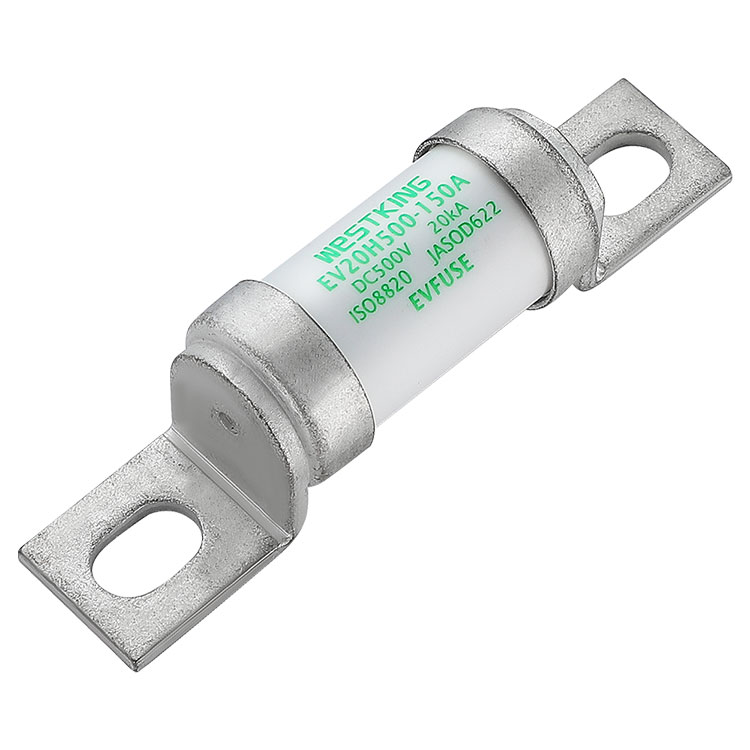

| EV20H500-(Amp) | 500VDC | 50A-150A |

| EV35H500-(Amp) | 500VDC | 200-400A |

| •Utilization category: | gEV |

| •Rated breaking capacity: | 20 kA |

| •Time constant: | 2±0.5ms |

| •Ambient temperature : | -40°C ... 125°C |

Material Description:

1- The fuse tube adopts high-strength 95% alumina ceramic,

2- The fuse element uses imported Japanese material and undergoes precise stamping.

Structural Process:

1- The metal copper parts are riveted and then welded again;

2- The internal quartz sand adopts the unique curing treatment process of WESTKING, preventing product detachment and arc spray caused by line faults during dynamic operation.

Standards

ISO8820-8

JASO D622

Manufactured under ITAF16949 quality system for compliance with automotive requirements

RoHS compliant

REACH declaration available upon request

KEY FEATURES/ADVANTAGES

Strong resistance to current surge

Tolerant of harsh driving conditions

Safe and reliable fusing characteristics

Double protection against overload and short circuit

Low temperature rise and power consumption, extending battery range

High breaking capacity

APPLICATIONS

Battery pack protection

BDU and PDU

Battery Junction Box for auxiliaries

EV/HEV

Electrical Energy Storage

Battery charger

Supercapacitor pack protection

Backup protection for DC relay / disconnector / switch

Maintenance Safety Disconnect (MSD)

Certifications

is09001 iatf16949

Origin

China

EV FUSE 500VDC EV10H500 protection for EV and battery pack

| Type | I2t (A2s) | Power loss 0.5 In(w) | Net weight (g) | |

| Melting | Clearing | |||

| EV10H500﹣10A | 350 | 420 | 0.60 | 12.34 |

| EV10H500﹣12A | 430 | 650 | 0.65 | |

| EV10H500﹣16A | 670 | 1280 | 0.75 | |

| EV10H500﹣20A | 800 | 1520 | 0.80 | |

| EV10H500﹣25A | 960 | 1820 | 1.00 | |

| EV10H500﹣30A | 1200 | 2100 | 1.20 | |

| EV10H500﹣35A | 1350 | 2600 | 1.50 | |

| EV10H500﹣40A | 1645 | 3250 | 2.10 | |

| EV10H500﹣50A | 2560 | 4896 | 3.20 | |

EV FUSE 500VDC EV16H500 protection for EV and battery pack

| Type | I2t (A2s) | Power loss 0.5 In(w) | Net weight (g) | |

| Melting | Clearing | |||

| EV16H500-20A | 650 | 2800 | 1.2 | 43.83 |

| EV16H500-25A | 1050 | 4000 | 1.5 | |

| EV16H500-32A | 1700 | 6300 | 1.8 | |

| EV16H500-40A | 3000 | 8500 | 2.0 | |

| EV16H500-50A | 5850 | 15600 | 2.5 | |

| EV16H500-60A | 8500 | 24500 | 2.8 | |

| EV16H500-70A | 10250 | 38000 | 3.0 | |

| EV16H500-80A | 14500 | 57600 | 3.2 | |

| EV16H500-100A | 21000 | 76000 | 3.5 | |

EV FUSE 500VDC EV20H500 protection for EV and battery pack

| Type | I2t (A2s) | Power loss 0.5 In(w) | Net weight (g) | |

| Melting | Clearing | |||

| EV20H500﹣50A | 380 | 750 | 1.10 | 85.6 |

| EV20H500﹣60A | 550 | 1100 | 1.40 | |

| EV20H500﹣70A | 750 | 1500 | 1.58 | |

| EV20H500﹣80A | 930 | 2280 | 1.80 | |

| EV20H500﹣100A | 1500 | 3010 | 2.30 | |

| EV20H500﹣125A | 1410 | 4202 | 3.10 | |

| EV20H500﹣150A | 2010 | 6100 | 3.68 | |

EV FUSE 500VDC EV35H500 protection for EV and battery pack

| Type | I2t (A2s) | Power loss 0.5 In(w) | Net weight (g) | |

| Melting | Clearing | |||

| EV35H500﹣200A | 3250 | 27000 | 6.20 | 226 |

| EV35H500﹣250A | 6000 | 48500 | 6.90 | |

| EV35H500﹣300A | 7100 | 60000 | 7.80 | |

| EV35H500﹣350A | 11500 | 90500 | 8.80 | |

| EV35H500﹣400A | 15000 | 110000 | 10.20 | |

EV FUSE t-I characteristics

temperature correction coefficient chart

Description:

1.The fuse operates normally within the temperature range of -5°C to 40°C, and no additional correction is required.

2.The allowable usage conditions are -40°C to 85°C.

3.Within the range of allowable usage conditions, refer to this table.

Let us introduce you to the WESTKING EVFUSE, the structure of a safe and reliable EV fuse should be like this

1-The metal end cap and purple copper legs are riveted and re-welded to ensure they will not fall off due to vibration.

2-The fuse tube is made of high-alumina ceramic, which withstands electric arc impact and does not deform under high temperatures.

3-The fuse element is precision-stamped from imported Japanese alloy materials, ensuring durability against current shock.

4-The arc extinguishing medium is high-purity quartz sand, which is selectively cleaned and processed.

5-A curing process developed by WESTKING is used to fix the quartz sand, preventing the fuse element from being pulled apart by vibrations and effectively reducing the intensity of electric arc impact.

6-An interference fit is used for the inner and outer end caps to reduce resistance.